-

Course Code

SRVT-008

Safety Relief Valve Sizing, Selection, Operation, Inspection & Maintenance

- Piping and pressure vessel industry, control and safety relief are of Most essential importance. Pressure relief valves are the last line of defense against Catastrophic failure or even loss of life. The course covers control and safety valve types And designs, materials, specification and selection, preventive maintenance procedures, Operation and troubleshooting. The course provides a basic and specialized knowledge of valve types and designs, Materials used to make valves, where various designs should and should not be used, Factors to consider in specifying a valve for a specific application, how to calculate flow Through valves, and valve maintenance and repair. Relief valves are the last line of defense in case of failure of pressure control and regulation systems. They automatically release excess pressure, preventing equipment damage and possible accidents. However, like any technical device, they require regular inspection, maintenance, and, if necessary, repair.

- This article is intended for inspection engineers, technical management, quality control specialists, and technical supervisors involved in the repair, inspection, operation, or maintenance of pressure relief valves. We will discuss the principles of operation of these valves, their design and application, installation and operation, common malfunctions, and the importance of adhering to international standards and regulations. Special attention will be paid to certification and requirements for organizations engaged in the repair of relief valves.

Learning Outcomes

- Familiarize participants with the functions and applications of control and safety

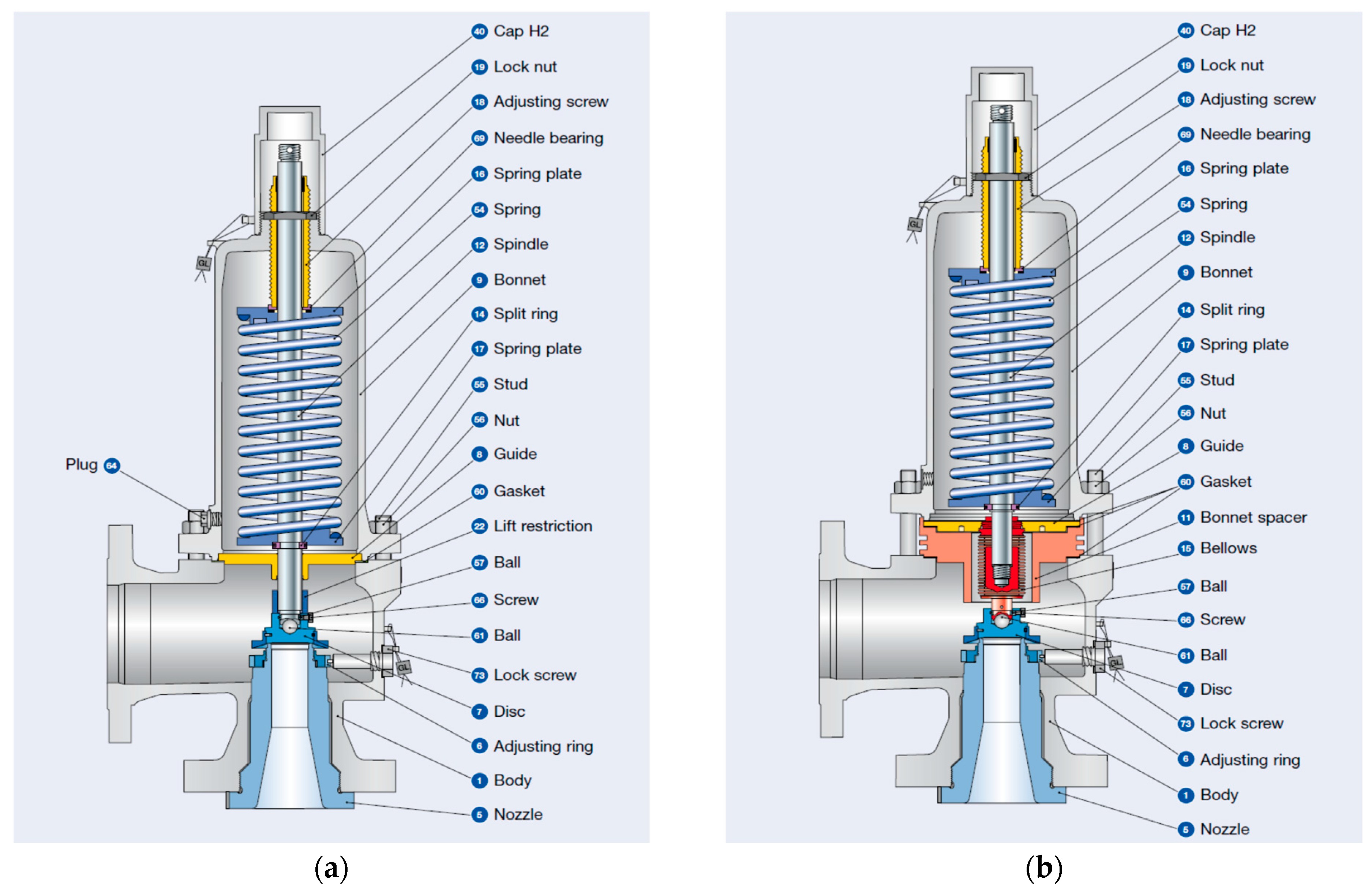

- Relief valves, their types, designs and components

- Introduce the participants to normal valve operation, bypass operations, abnormal

- Conditions, inspection and preoperational checks

- Apply troubleshooting procedures for safety relief valves and illustrate the process of nameplate stamping

- Enable appropriate control and safety valve sizing and selection for liquid and gas

- Train participants to install, disassemble, clean, inspect, align, and reassemble a Variety of control and safety valves

- Identify the development and application of pressure relief valves and determine the installation requirements for pressure relief valves

- Training and qualification of personnel

Course Contents

- Welcome & Introduction

- Fundamental principle

- Hydraulic fluids and their properties

- Hydraulic pumps and intensifiers

- Basics of hydraulic flow in pipes

- Air and gas basics

- Compressors and fans

- Pneumatic components and circuits

- Pressure measurement

- Hydraulic valves and circuits

- Standard definitions

- Directional control valves

- Pressure control valves

- flow control valves

- Safety relief valves

- Valve material

- Gate valves

- Globe valves

- check valves

- Butterfly valves

- Ball valves

- plug valves

- Diaphragm valves, sizes, classes, and ratings,

- Valve selection, function and selection, process applications, valve selection Factors,

- Valve design, control valve trim, control valve safety, valve sizing for liquid, gas And vapor applications.

- Preoperational checks

- Normal operations

- bypass operations

- Valve inspections

- Abnormal valve conditions, and automatic valve operation

- Safety valve operation, disassembly, removing the disc assembly, blue checking The seat and disc

- performing spindle run out, reassembly, installation and setting

- Methods for evaluation of mechanical components, mechanical components, Electrical components

- removing a valve actuator, disassembly, and reassembly

- limit switch adjustment

- torque switch adjustment

- Operational tests

- Mechanical troubleshooting, and electrical troubleshooting

- accepted methods for cleaning

- adjusting and lubricating various components

- Codes and recommended standards of practice, fault finding instruments, preventive maintenance

- Review and Open Discussion

Our Methodology

- Make coaching and monitoring innovative and using modern

- Media training also using on the go training by using interactive means and focusing on

- The exercises, practical applications and real situations study

- Live delivery method, instructor-led training

- Experienced consultant, trainers, and professional

- Qualified trainer with high-level experience

Attendance Reports

- Send daily attendance reports to training departments

- Send full attendance report to training dep. by the end of the course

- Attend 100 % from the course days also provide daily

- Issue attendance certificate for participant who attend minimum 80% from the course duration

Pre/Post Reports

- Pre- assessment before starting training

- Post assessment after finishing training

- Full report for the difference between Pre-& Post assessment

Who Should Attend

- Engineers, operators

- Maintenance technicians in the power generation, oil, chemical, inspection, troubleshooting or repair

- Who are involved in the sizing, selection, operation, inspection, maintenance and troubleshooting of valves

- Process engineers, mechanical engineers, piping engineers, pipelines and pressure vessels engineers